Unsaturated Vinyl Ester Resin

Because they are easy to process and have very good physical properties especially when combined with fibre reinforcement finished products made of these polymers have become an integral part of our daily lives.

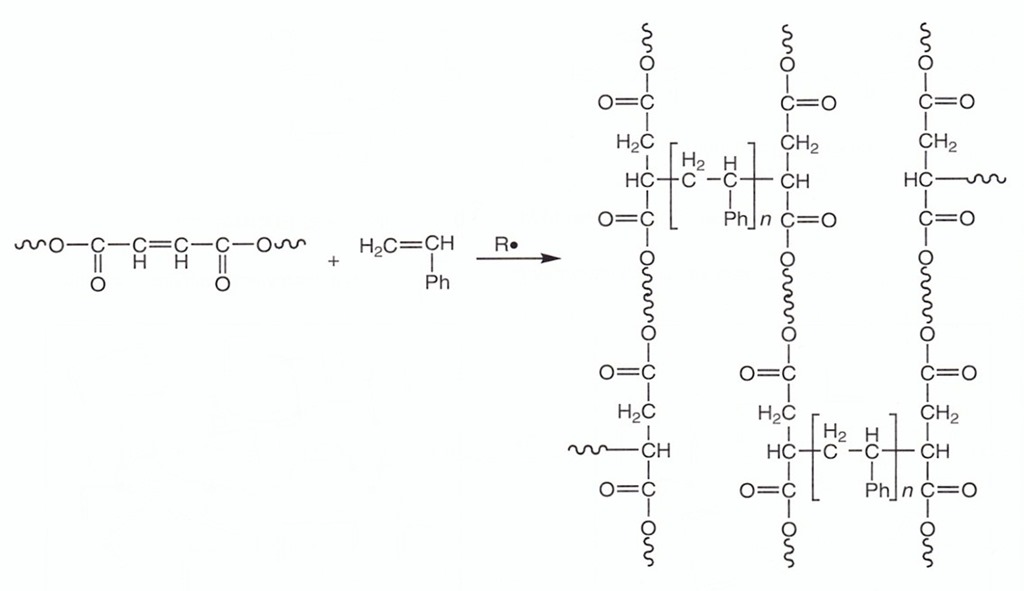

Unsaturated vinyl ester resin. They are produced by the addition of α β unsaturated carboxylic acids to epoxy resins. Vinyl ester resins are produced by the reaction esterification between an epoxy resin and an unsaturated monocarboxylic acid. Essentially they comprise a base of polyester resin strengthened with epoxy molecules in the backbone of the molecular chain. These invariably use styrene as the reactive diluent and moisture absorption is therefore at a low level.

Therefore vinyl ester resins may be considered as the polyaddition products of these monounsaturated monomers e g. The two main types of epoxy resins are bisphenol a diglycidyl ether dgeba and epoxy phenol novolac epn. Vinyl esters also use peroxides e g. Polyester resins also known as unsaturated polyester resins upr combined with fiberglass reinforcements have been the building blocks of the composites industry for decades these formulations provide low cost ease of handling quick cure and high strength to create a wide variety of.

Within the corrosion resistant composites industry both unsaturated polyester and vinyl ester resins are used. Polyester and vinyl ester resins are the most commonly used matrix resins to create composite parts. However polyester resins may have polar end groups or contain unreacted monomers which tend to enhance its sensitivity to water.